| Abstract |

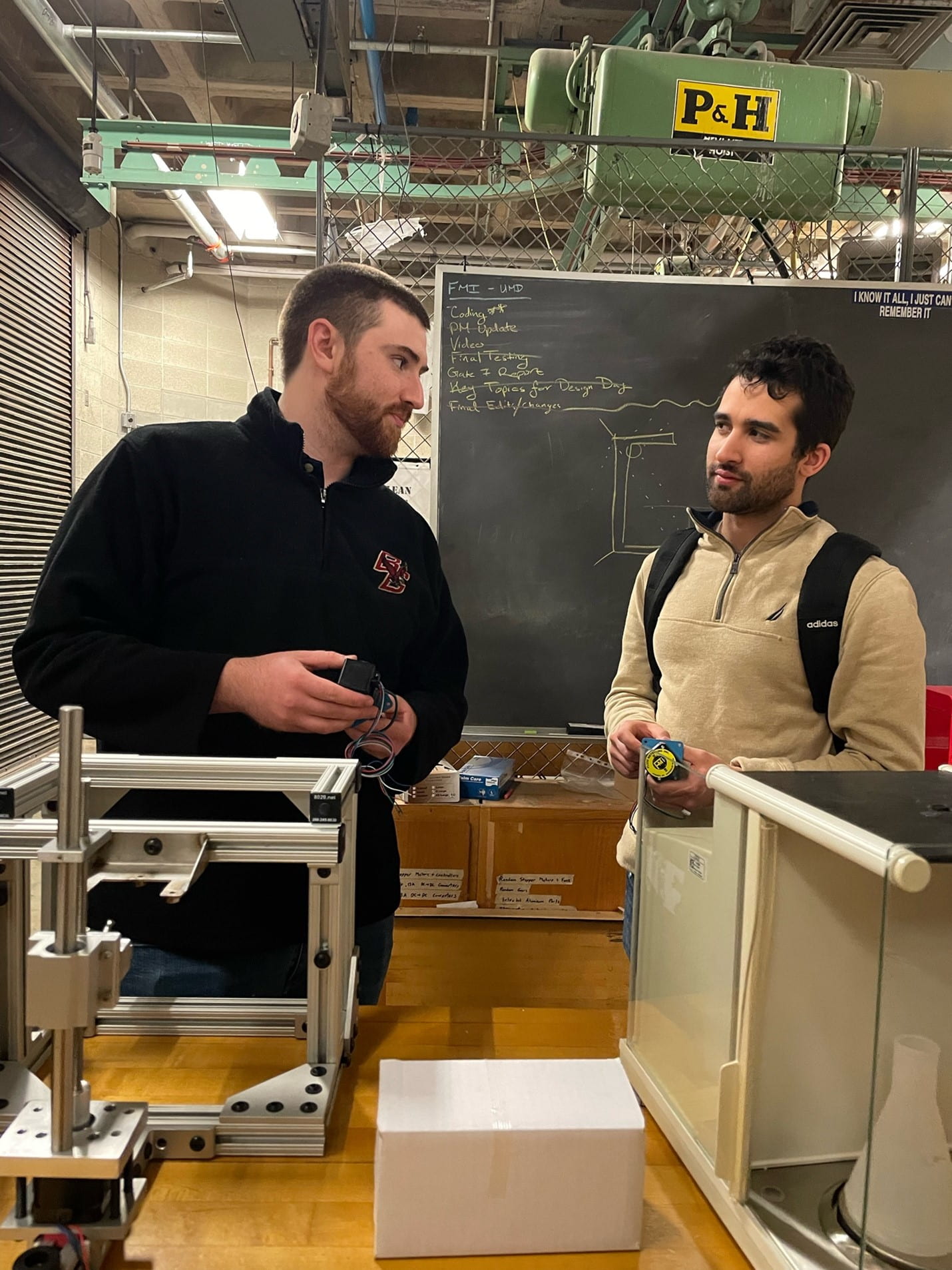

CCRAM Calibration has been tasks to make a calibration tool for Fluid Metering Inc. (also referred to as FMI ). The tool must also account for the increased volume of pumps manufactured by the sponsor so that FMI will be able to calibrate pumps at a faster rate than their current calibration process. The tool that the team designs must be within a tabletop area of 3’ x 2’ and be able to attach to the current frame in FMI’s production setting. The tool will help to save FMI money in wages as their manufacturing and demand increases, this happens in the form of saving money on wages and operating time or run time. CCRAM Calibration is also working to shorten the average calibration time with the implementation of this tool, where the current process takes between 4-8 minutes. The team also had to complete this using the frame and engineering workbench coding provided by FMI. The coding base was from Visual Basic, the software used on excel, and the frame was a general testing frame that was not in the production setting. With these aspects in mind, CCRAM had to provide a tool that worked with the equipment provided and be redesigned to fit the production material found in the sponsors facility. Multiple designs were sketched out, printed, and teste to attempt to attain the best design with minimal impact to the sponsor’s current process. The team has had to adapt and learn how to work with many fixed constraints and conform the design to the constraints so that the best quality product could be produced for the project and the future implementations of the product. |